When it comes to repairing sunken concrete, there are two common methods: mudjacking (also known as slabjacking) and polyurethane foam injection. Both methods are aimed at lifting and leveling the concrete, but they vary significantly in terms of materials, processes, durability, and benefits. Let’s delve deeper into the comparison and discover why polyurethane foam stands out as the superior choice.

Before you make a decision on leveling your concrete, it’s crucial to be informed about the various methods and their implications. At Concrete Polyfix, we believe in empowering our clients with knowledge to make the best choices for their properties. Dive into our comprehensive guide that outlines the key differences between various concrete leveling techniques. Making an informed decision can save you time, money, and potential future complications. Trust Concrete Polyfix to guide you through this process, ensuring that your concrete leveling choice is both informed and optimal for your specific needs.

Some of the main differences between Polyurethane Foam and mudjacking

The Process

Mudjacking: This involves drilling large holes into the sunken concrete and pumping a mixture of cement, soil, and water beneath the slab. The mixture, often called “mud” or “slurry,” fills the voids under the concrete and forces it to rise.

Polyurethane Foam: With this method, smaller holes are drilled, and a two-part polyurethane foam is injected. As the foam expands, it fills the voids and lifts the concrete to its original position.

Hole Size & Appearance

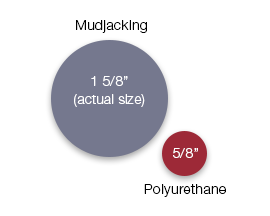

Mudjacking: Typically requires larger holes (around 1-2 inches in diameter) which can be more noticeable after the process is complete.

Polyurethane Foam: Uses smaller holes (about 5/8-inch in diameter), leading to a less invasive appearance and easier cosmetic repair.

Weight & Soil Displacement

Mudjacking: The mud or slurry is heavy and can add weight to the underlying soil, potentially leading to further soil displacement and settling over time.

Polyurethane Foam: It’s significantly lighter than mudjacking material, thus not adding unnecessary weight to the soil underneath. This ensures less likelihood of future sinking.

Cure Time

Mudjacking: The slurry takes longer to set, meaning you might have to wait longer before you can use the repaired area. (meaning the slab(s) may be unusable for several hours if not a full day)

Polyurethane Foam: Sets and cures quickly, often within minutes, allowing for immediate use of the repaired surface.

Durability & Waterproofing

Mudjacking: The mud mixture can break down over time and might not offer any waterproofing benefits. This can lead to further erosion and sinking.

Polyurethane Foam: Not only is it durable, but it’s also water-resistant, meaning it won’t wash away or degrade in wet conditions. This ensures a longer-lasting repair.

Environmental Impact

Mudjacking: Uses natural materials, but the large amount of material needed can have a greater environmental impact in terms of resource extraction and transport.

Polyurethane Foam: While it’s a synthetic material, the small amount required minimizes its environmental footprint. Additionally, it doesn’t contribute to further soil erosion.

Why Choose Concrete Polyfix?

Given the advantages of polyurethane foam over mudjacking, it’s clear that for most applications, foam offers a more efficient, long-lasting, and aesthetically pleasing solution. At Concrete Polyfix, we specialize in polyurethane foam concrete lifting, ensuring our clients receive the best results possible.

Revive your sunken concrete with Concrete Polyfix – where quality, durability, and efficiency converge. Contact us today to learn more or schedule an assessment.

Faster and Easier to Install

Polyurethane concrete raising requires just a few 5/8″ drill holes, compared to the larger holes used in mudjacking. The install takes less manpower and the process is much cleaner—there’s no muddy mess left behind. Our method takes about 15 minutes to cure, compared to 4-6 hours after mudjacking. You’ll be able to use your concrete almost immediately after repairs are complete.

More Versatile

Polyurethane concrete raising can be used for a wide variety of applications. While mudjacking can be used for leveling driveways or sidewalks, polyurethane foam can level driveways, sidewalks, concrete floors, and even public highways.

Lighter

Due to its lightweight quality, polyurethane does not cause additional pressure or add weight to the weakened soil beneath the slab. Unlike mudjacking, which weighs approximately 100 pounds per cubic foot of material, polyurethane foam weighs only 2 pounds per cubic foot and can support the concrete slab without causing further stress.

Longer Lasting

Polyurethane doesn’t shrink or break down over time. It increases your concrete’s strength and ability to bear weight while keeping problematic moisture out.

Better for the Environment

Mudjacking or replacing concrete creates a lot of waste. Polyurethane is non-toxic and environmentally friendly.

GET AN ESTIMATE

We’re happy to answer any questions you have in order to find the concrete solution best for you.

We want to help you make the choice that’s right for you. Contact us or give us a call!